Vizag

Gateway for iron-ore exports &

coastal shipping on east coast of India

Commissioned year: 2018, Divested year: 2024

Essar O&M experience: 94 MMT

8000 TPH largest ship loader capacity

~ 200000 DWT berth capacity

2 X 2700 TPH stackers

3 X 4000 reclaimers

2 X 27 tips per hour twin tippler

30 tips per hour rotary tippler

Unveiling the largest iron ore export terminal in India at Visakhapatnam port

The terminal could accommodate super cape size vessels and had dedicated rail-connectivity with high-grade iron-ore sources. The terminal was divested in February 2024 to AMNS India was integrated with a pellet plant in Vizag through a fully mechanized conveying facility with a 6.7km shipping conveyor system.

Facilities

Vessel berthing

The facility features two outer harbor berths designed to streamline pre-commencement and sailing procedures. These berths are capable of accommodating cape size vessels of up to 200,000 deadweight tons (DWT) with a draft of 18.5 meters and a length overall (LOA) of up to 325 meters.

Crane and conveyor facilities

~9.5km conveyor stream, equipped with cold fog system that reduces dust pollution and ensures a cleaner environment.

Cargo handling & Loading

Rakes received from Indian Railways are tipped through three wagon tipplers at the terminal, then efficiently conveyed to the fully mechanized stockyard for loading vessels at an impressive 8,000 tonnes per hour. Vizag facility, the nation’s largest ship loader, enhances exports and coastal movement sustainably.

Storage

The facility features a fully mechanized stockyard spanning 30 acres, equipped with a string of stackers and reclaimers, enabling efficient and eco-friendly handling of cargo. With a stacking capacity of up to one million tonnes (MMT), it ensures optimal storage capabilities.

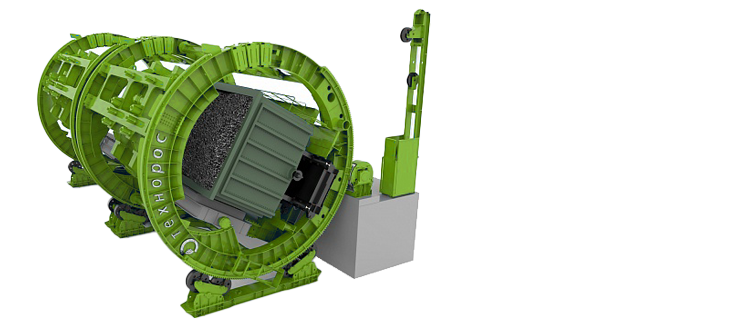

Wagon tipplers, stackers and reclaimers

The facility is equipped with three wagon tipplers, two stackers with a capacity of 2,700 TPH each, and three reclaimers capable of handling 4,000 TPH each. These components ensure efficient and high-capacity material handling operations.

Services

The services are being offered with an aim of faster turn-around of the vessels, zero congestion of vessels at anchorage, zero spillages, zero foreign contamination, and zero dust-emissions.

Pilotage, tug and tow services

The Vishakhapatnam port trust provides various vessel-related services such as pilotage, tug and towing services.

Industry integration

The terminal is also integrated with adjacent pellet plant in Vizag through a fully mechanized facility and is also accessible to other adjacent industries for necessary mechanized integration.

Emission control

The Vizag terminal’s state-of-the-art sprinkler systems and cold fog system ensures the suppression and containment of dust in the most eco-friendly manner possible.

Services

Services

The services are being offered with an aim of faster turn-around of the vessels, zero congestion of vessels at anchorage, zero spillages, zero foreign contamination, and zero dust-emissions.

Vessel berthing

The facility has two berths in the outer harbor, saving time for pre-commencement and sailing. These berths can accommodate cape size vessels up to 200,000 DWT, with a draft of 18.5 meters and an LOA of up to 325 meters.

Storage

The fully mechanized stock yard can store up to one million tonnes of cargo through a string of stackers and reclaimers. It handles the cargo in the most efficient and ecofriendly manner.

Pilotage, Tug and Tow Services

The Vishakhapatnam Port Trust provides various vessel-related services such as pilotage, tug and towing services.

Industry integration

The terminal is also integrated with adjacent pellet plant in Vizag through a fully mechanized facility and is also accessible to other adjacent industries for necessary mechanized integration.

Emission control

The Vizag terminal’s state-of-the-art sprinkler systems and cold fog system ensures the suppression and containment of dust in the most eco-friendly manner possible.

Cargo handling

Rakes are received by the terminal from the Indian Railways at an exchange yard and are tippled through a system of three wagon tipplers for onwards mechanized conveying. From the fully mechanized stock yard cargo is then reclaimed for onward loading of vessels at a speed of 8,000 TPH in the most efficient and ecofriendly manner.

Connectivity

Road

Vizag Port is connected to north and south India via National Highway NH5, which runs from Chennai to Kolkata.

Rail

The terminal directly links to the Chennai-Visakhapatnam-Howrah rail corridor for mining operators' access easily.

Air

Visakhapatnam Airport is 10 km from the Port, which is well connected to all major domestic and international airports.

Milestone

Awards